How to improve the productivity and to reduce the wear-down of tool

Our solution: Co-JJINN high pressure coolant system is your best choice

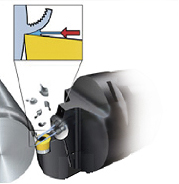

The principle of High Pressure Coolant (HPC) aims to transfer the generated heat by machining process to lubricant. This can reduce the wear-down of tool. and enhance of cutting speed . Such improvement on cutting speed can eliminate unexpected shut-down and boost ratio of utilization. High Pressure Coolant System usually refers to coolant pressure up to 70bar. Co-JJINN high pressure system can boost coolant pressure up to 300 bar. The utilizing principle is to allow nozzle shoot lubricant on the right position in a high speed.

High pressure coolant system can be utilized for diverse application such as turning, milling, and drilling process

High pressure coolant system can be utilized for diverse application such as turning, milling, and drilling process.

For example : Titanium alloy and stainless steel is very challenging material. For turning machining , long sting chip is always troublesome , especially for turret exchanging tool , semi-precision and precision process. High pressure coolant improves the control of chip ,reducing the unexpected suspension, and boost ratio of utilization . During machining, HPC can speed up cool-down of the tool and rapidly discharge chip , not only acquiring a better service life of tool, but also ensuring a excellent coolant flow allowing a much safer process .

Implementing automatically unmanned production , high pressure coolant system is definitely required.

HPC can obviously improve the control of chip. And therefore unmanned production was implemented. Meanwhile, boost of cutting speed and enhancement is also accomplished. Titanium alloy and nickel-based alloy are also the same token.

Excellent Remuneration.

Adopting HPC as a solution usually takes only one year as remuneration. Nowadays, a lot of machines adopts HPC as a standard equipment. However, a retrofit over old machine is also profitable. That is why more and more users adopt HPC . The essential features of HPC (1) shorten of process cycle time. (2) Reduce the suspension (3) stabilize machining craftsmantship (4) Boost of product quality.

conclusion

HPC provides a lot of benefit for several application. New machine incorporated with HPC is becoming increasingly evident trend. It provide better control of chip and longer service life , and therefore enhance cutting efficiency and ratio of utilization.